A completely new and therefore less familiar method is "Cyclic Nucleation" (CNp). It offers a safe processing solution for those tasks that formerly could not be done using a water-based cleaning system and, where relevant, were also difficult to complete with solvent-based systems.

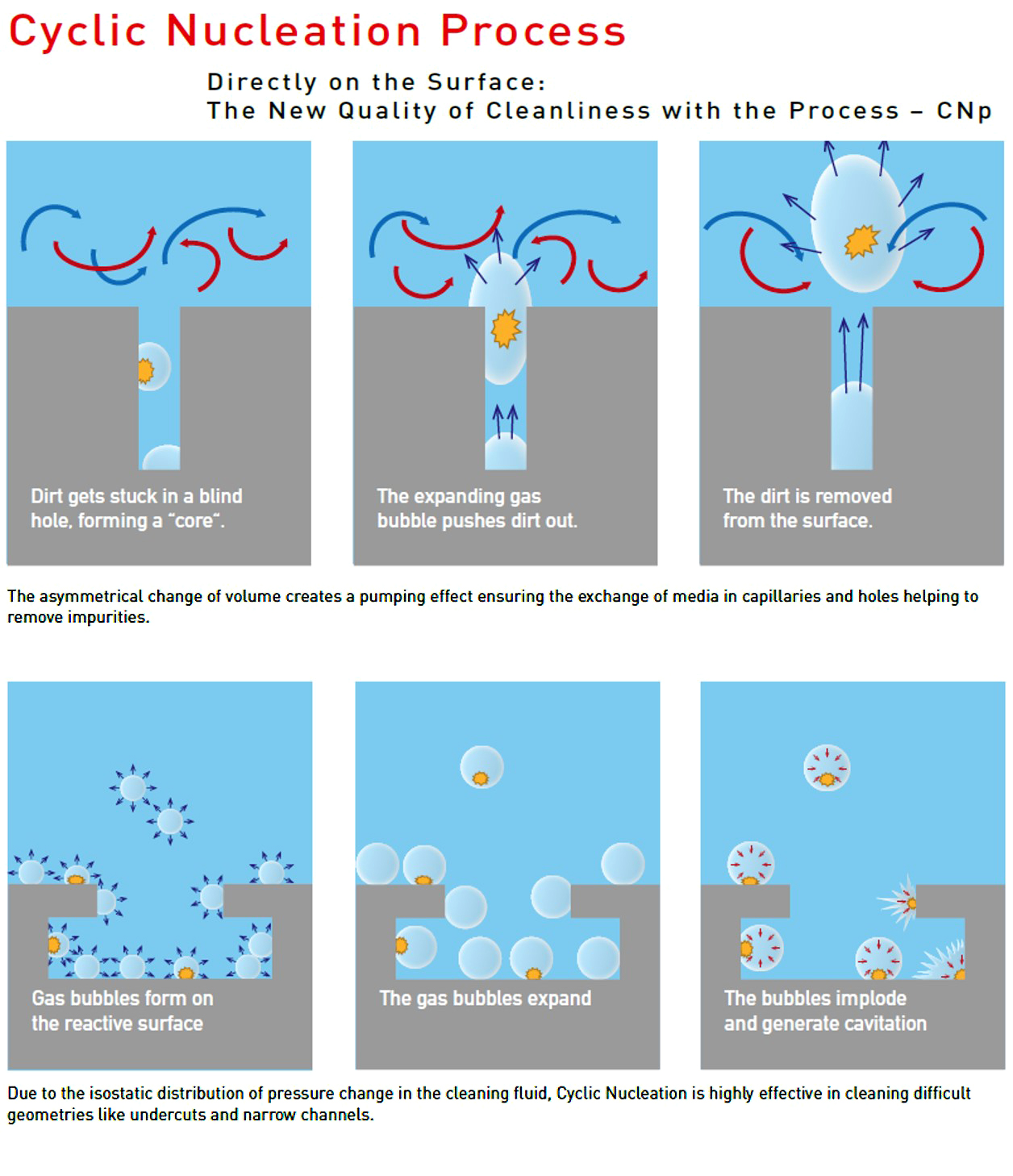

The CNp technology (cyclic nucleation process) is a vacuum flood cleaning method patented in the USA and China and for which a patent application has been filed in Europe. This works according to the cyclic nucleation principle, an alternating pressure method with particular strengths for cleaning capillary structures and complex geometries, such as are found universally in industrial production. The effective mechanisms are characterized first by the cavitation effect on the entire surface of the component directly in contact with the media and between the component and the contamination. In addition, by the generation of an asymmetric flow in capillary, and thus hard to reach, areas of the component.

This is how cyclic nucleation enables hitherto unachieved results not only in the conventional areas of fine and deep cleaning (electronics/semiconductor industry, medical systems and the optical industry). In other sectors (such as automotive), it also offers considerable potential in comparison with conventional methods that have met "normal" particulate and film requirements. This is because capillary conditions can also exist in densely packed goods or bulk items in close proximity to each other and, with earlier methods, represent a challenge for cleaning, flushing and drying processes. Fine holes, e.g. in fuel injection technology, or concealed and complex interior geometries, as in cooling elements, can finally be brought to a higher purity level using the CNp method.

How it works

The CNp effect can be generated using familiar and conventional basic process engineering principles, in which a filled and sealed vacuum chamber is brought into contact with the medium (e.g. a cleaning fluid). The resultant gas bubbles are formed on all reactive surfaces, even in complex structures such as capillaries and holes. If there is a sudden removal of the vacuum, these again fall into each other (implode) and generate a pressure wave (cavitation effect) with a perceptible mechanical effect on the entire surface of the components – even in concealed or capillary areas.

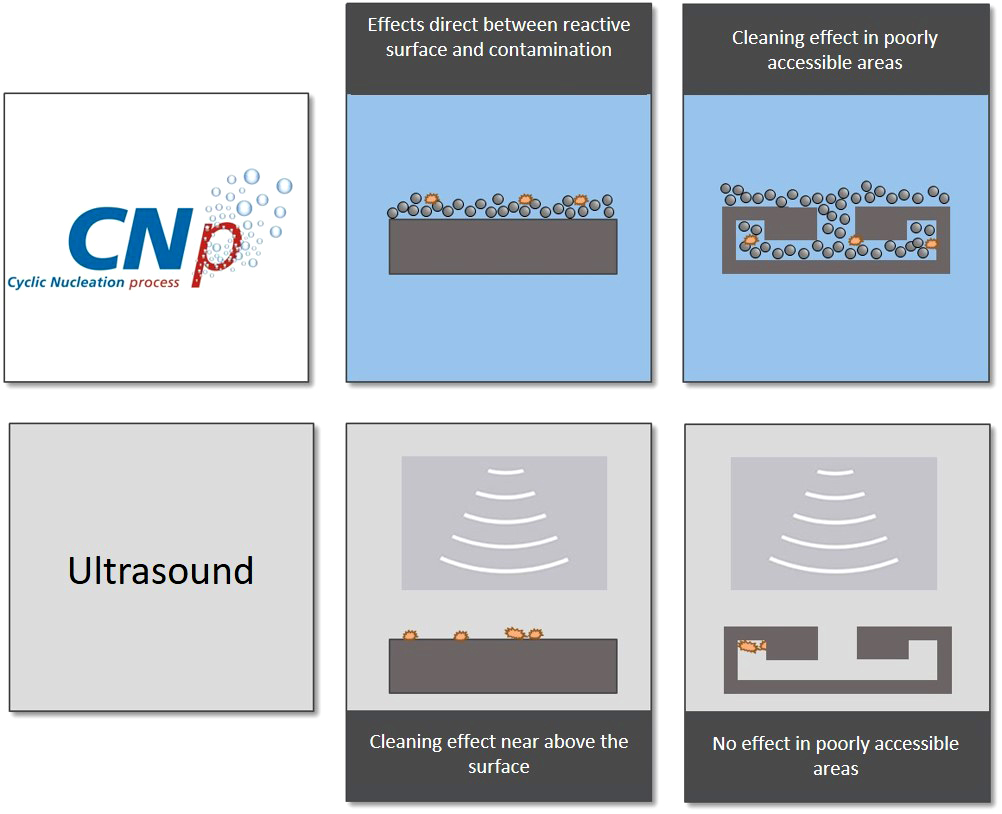

The crucial mechanical washing effect, the actual innovation, consists in the provision of a firmly set cycle between a defined lower switching point in a vacuum and a higher switching point in negative or, if need be overpressure, which is often repeated at random and can be varied. Hence the term "Cyclic nucleation". The physical effects are in the main the same as those familiar from conventional ultrasound processes. The cavitation effect indeed tends to be weaker, but this is also revealed between the impurity and the substrate – and this on the entire surface of the component, even inside complex 3D structures, into which ultrasound can penetrate only under certain conditions. This method can therefore be used alone or even in addition to conventional cleaning methods.