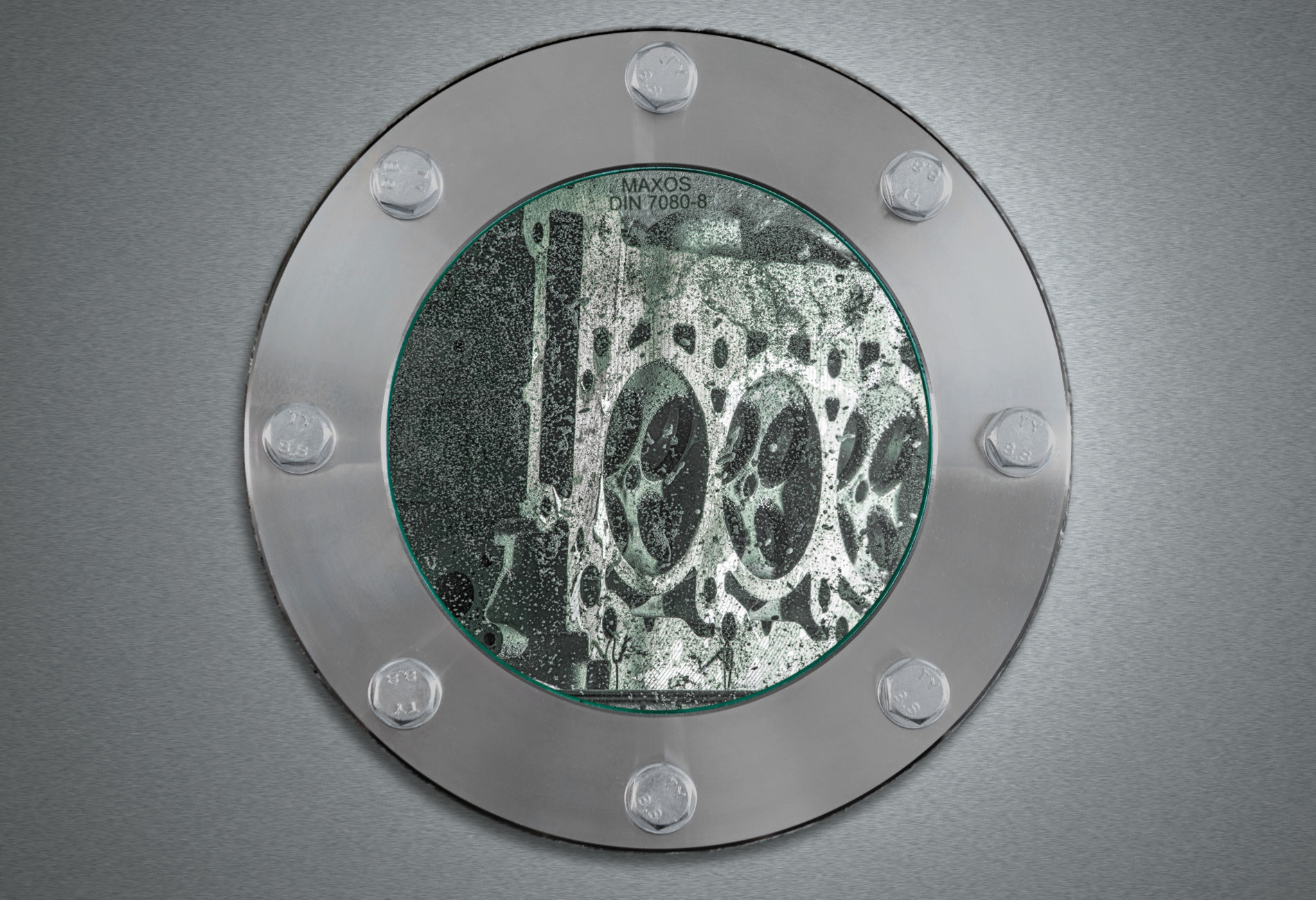

Ultrasound cleaning systems have proved themselves in all sectors of industry. Even with fine and deep cleaning tasks (films and particulates), as well as in some coarse cleaning processes, ultrasound, where necessary in combination with other flood cleaning methods, has proved itself as very efficient and powerful. Ultrasound methods can be used in all immersion cleaning systems.

How it works

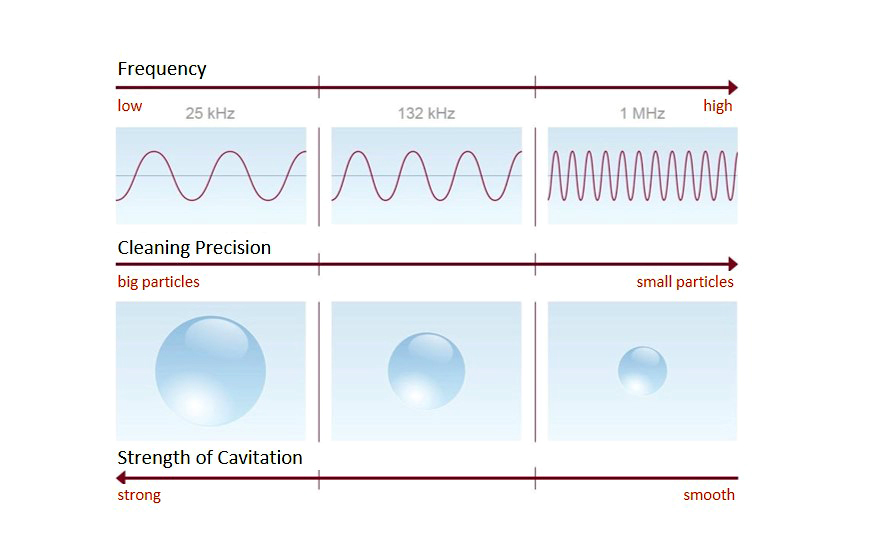

Sound is a pressure wave which is moved both in elastic media and in gases, liquids and solids. The designation ultrasound covers a frequency range of between 22 kHz and 1 MHz. Depending on the application field, all possible frequencies can be found in cleaning technology. At the same time, the mechanical washing force is dependent on the frequency in question. The lower this is, the stronger the mechanical effect on the surface of the component. The cavitation effects desired for cleaning are dependent on these factors - frequency, pressure amplitude, temperature and the properties of the fluid (viscosity, vapour pressure). In addition to cavitation, ultrasound also generates forces, such as micro-flows and an acoustic flow. This helps to transport the dissolved impurity away. At a lower frequency, it is stronger, but further removed from the boundary layer. The higher the frequency, the closer the flow approaches the surface of the component. However, the strength falls off severely. In addition to the suitability for mechanical washing being inadequate in concealed areas, the weakness of the method here is clear.